Over the past 70 years Benkan Kikoh has evolved from small-scale factory for Buttwelding Fittings to the leading manufacturer in Japan.

Benkan Kikoh has been accumulating and inheriting the technical capabilities and the reliability of manufacturing from Benkan and Sumitomo Metal Industries. In detail, NIPPON BENKAN KOGYO (former BENKAN Corporation) established in 1947 and FUSO KIKOH (former NIPPON STEEL & SUMIKIN KIKOH COMPANY, LTD) became independent from Sumitomo Metal Industries in 1957.

Our company succeeded in the domestic production of buttwelding fittings, built a factory in Ota-ku, Tokyo in 1951, and started manufacturing.

We have gradually expanded our domestic factories, current Amagasaki factory started manufacturing the buttwelding fittings in 1953, Kiryu factory (current Kiryu branch) was established in 1960, Osaka factory was established in 1965, and Yabutsuka factory (current Kiryu factory) was established in 1971.

Regarding the certification, we applied it as a trailblazer in Japan, our factories have been certifying by JIS (Japanese Industrial Standards: B 2311, B 2312, B 2313, B 2309), ISO 9001, various ship classifications (NK, DNV, LR, ABS, and BV), and EU / PED (97 / 23EC).

We also comply with Japanese laws such as the Electricity Business Act (including private sector certification), Gas Business Act, High Pressure Gas Safety Act, and Reactor Regulation Act.

We started overseas production in Thailand (currently, Thai Benkan) since 1987 and Vietnam (currently, Benkan Vietnam BV2) since 1995 with our own technology, and we have been walking as a leading company.

We can supply the fittings sizes from NPS 1/2 (DN 15) to NPS 80 (DN 2000) with various material grades such as carbon steel, low alloy steel, high alloy steel, stainless steel, 6Mo stainless steel, duplex stainless steel, nickel alloy steel, aluminum alloy steel, titanium alloy steel, and high yield steel.

Regarding various tests and inspections, we have the equipment and qualifications for necessary tests and inspections such as mechanical tests and non-destructive inspections, excluding special tests (HIC, SCC etc.) and we meet a variety of requests.

Our fittings are used in a wide range of industries from nuclear power plants, thermal power plants, geothermal power plants, refining / chemical plants, LNG / LPG plants, oil / gas pipelines, shipbuilding, paper mills, construction, pharmaceutical plants, garbage incinerators.

Benkan Kikoh's Buttwelding Fittings business will continue to sustainable development as a core industry that supports lifelines while taking on new challenges.

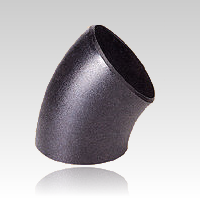

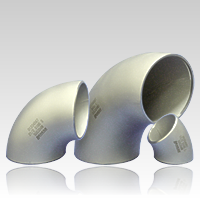

Manufacturing Elbows

Mandrel method (Hot Forming)

One of the most common manufacturing methods for manufacturing Elbows from pipes. After heating the raw material, it is pushed over a die called a "mandrel" which allows the pipe to expand and bend simultaneously. Applicable to a wide size range.

View AnimationExtrusion method (Cold Forming)

Using raw material with the same diameter as finished product, pipe is pushed through a die and formed into its desired shape. Usually applied to stainless steel, small to medium sizes.

View Animation"UO" method

After raw material plate is cut out into a specially designed shape, it is shaped first into an U-shape using a die and then into an O-shape (tubular form) using another die, finished with a single weld. Usually applied to stainless steel and non-steel material, small to medium sizes.

View Animation"Monaka" method

One of the most used methods for manufacturing Elbows from plates. After two pieces of raw material plates are cut out symmetrically, each piece are press formed and welded together, which somewhat reminds us of the Japanese delicacy, "Monaka." This method is applicable to various materials and can even be applied to large items with diameters over 1 meter. It has two seams and special welding technology in use to meet various standards required by our clients (electricity, gas pressure vessels, etc.,) from whom BENKAN KIKOH Corporation products continue to receive high acclaim.

View AnimationHot Forming Die Bending method

After heating raw material pipe, it is press formed and corrected using different dies. The process may be repeated as needed to obtain the required shape, size, wall thickness, etc. Usually applied to thick-wall items that cannot be bent on a mandrel die.

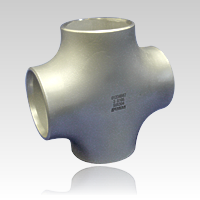

View AnimationManufacturing Tees

Hydraulic Bulge method (Cold Forming)

After cutting and placing raw material into a die, the pipe is pressed as hydraulic pressure pushes out the branch. The Tee is pressed against the die, leaving the finished product to have a truly smooth outer surface.

View AnimationExtrusion method (Hot Forming)

Using raw material with a bigger diameter than the finished product, the branch outlet is extruded from pipe while the main body is being pressed. The outlet's wall thickness can also be adjusted as needed. Applied to Tees with large diameters, heavy wall thickness and/or special material with challenging workability that cannot be manufactured using the hydraulic bulge method.

View AnimationSteel Plate Welding method

Manufacturing methods are similar to Elbows, using steel plates as the raw material. Includes the UO-method, Monaka method and Throat-welding method.

"UO" method: After raw material plate is cut out into a specially designed shape, it is shaped first into an U-shape using a die, then the branch pipe is formed and then shaped into an O-shape (tubular form) using another die, finished with a single weld on the opposite side of the branch pipe. Usually applied to large diameter items used in severe conditions.

"Monaka" method: Two pieces of raw material plates cut out symmetrically are press formed and welded together. Usually applied to large-diameter items.

Throat-welding method: Mainly used for stainless and non-metal items, this method is similar to UO-method but with the weld on the same side as the branch pipe and the "branch throat." Usually applied to low-pressure, corrosion-resistant items.

Manufacturing Reducers

Outer Die method

One of the most common method for manufacturing Reducers, using an outer die. Raw material pipe is cut and pressed in an outer die, compressing one end of pipe into a smaller size.

View AnimationPlate Forming method

Plates can also be used to manufacture Reducers. In an UO method, plate is cut in a specially designed shape which is formed into an U-shape and an O-shape respectively, then finished with a single weld seam. The "Monaka" method is also available and is similar to that of Elbows and Tees, using two symmetrically cut plates formed and welded together with two seams. Both methods are used for large diameter items.

View AnimationCaps

Manufacturing Caps

Deep Drawing method

One of the most common manufacturing methods for caps, where plate is cut out in a circle and formed by deep drawing.

View AnimationProduction Range

The most appropriate manufacturing process for each product will be decided with consideration of its material, sizes, shape, use, standards and special properties.

There are numerous methods for manufacturing Elbows alone.

| Type | Shape | Meterial | ||

|---|---|---|---|---|

| Carbon Steel | Alloy Steel | Stainless Steel | ||

| Elbows | Seamless | 1/2B--40B | 1/2B--40B | 1/2B--40B |

| 130t max | 130t max | 130t max | ||

| 1-Seam | - | - | 1/2B--14B | |

| 20t max | ||||

| 2-Seam | 14B--80B | 14B--80B | 14B--80B | |

| 90t max | 90t max | 90t max | ||

| Tees | Seamless | 1/2B--26B | 1/2B--26B | 1/2B--26B |

| 130t max | 130t max | 100t max | ||

| 1-Seam | 16B--48B | 16B--48B | 16B--48B | |

| 100t max | 100t max | 90t max | ||

| 2-Seam | 22B--66B | 22B--66B | 22B--66B | |

| 100t max | 100t max | 100t max | ||

| 3-Seam | 8B--40B | 8B--40B | 8B--40B | |

| 75t max | 75t max | 75t max | ||

| Reducers | Seamless | 3/4--40B | 3/4--40B | 3/4--40B |

| 110t max | 110t max | 110t max | ||

| 1-Seam | 16B--80B | 16B--80B | 3/4B--80B | |

| 100t max | 100t max | 100t max | ||

| Caps | Seamless | 1/2B--80B | 1/2B--80B | 1/2B--80B |

| 120 max | 120 max | 120 max | ||

- In the table, the top figures show Outside Diameter, and the bottom figures indicate wall thickness (mm).

- Please contact us for more specific details.

Fittings Dimension List

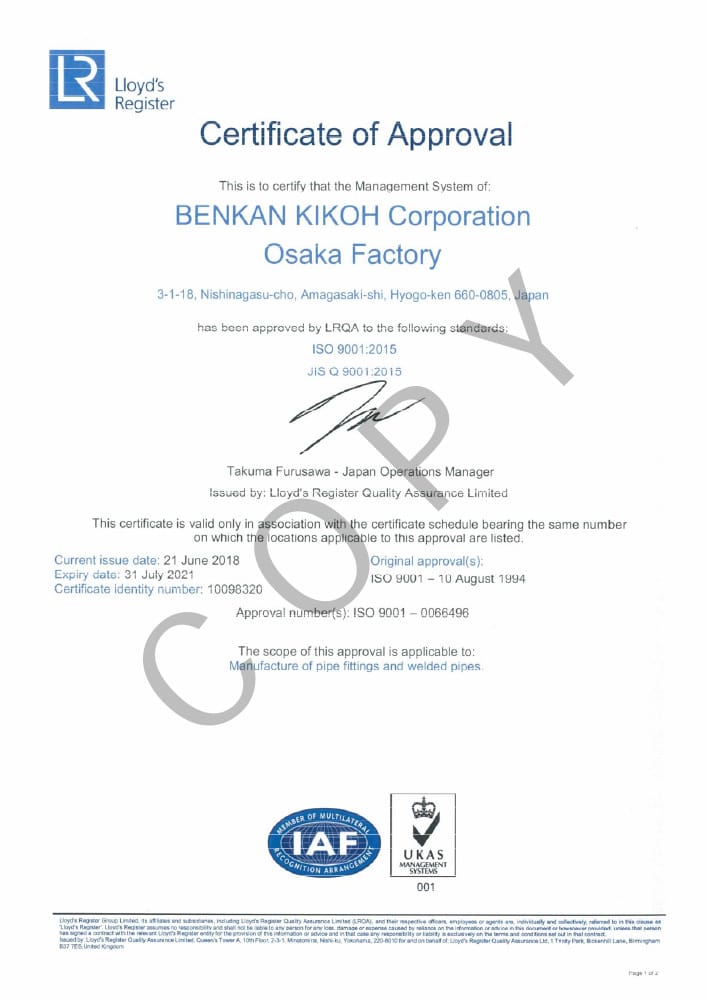

ISO Approval Certificates

ISO 9001:2015, JIS Q 9001:2015

(Kiryu Factory)

ISO 9001:2015, JIS Q 9001:2015

(Osaka Factory)

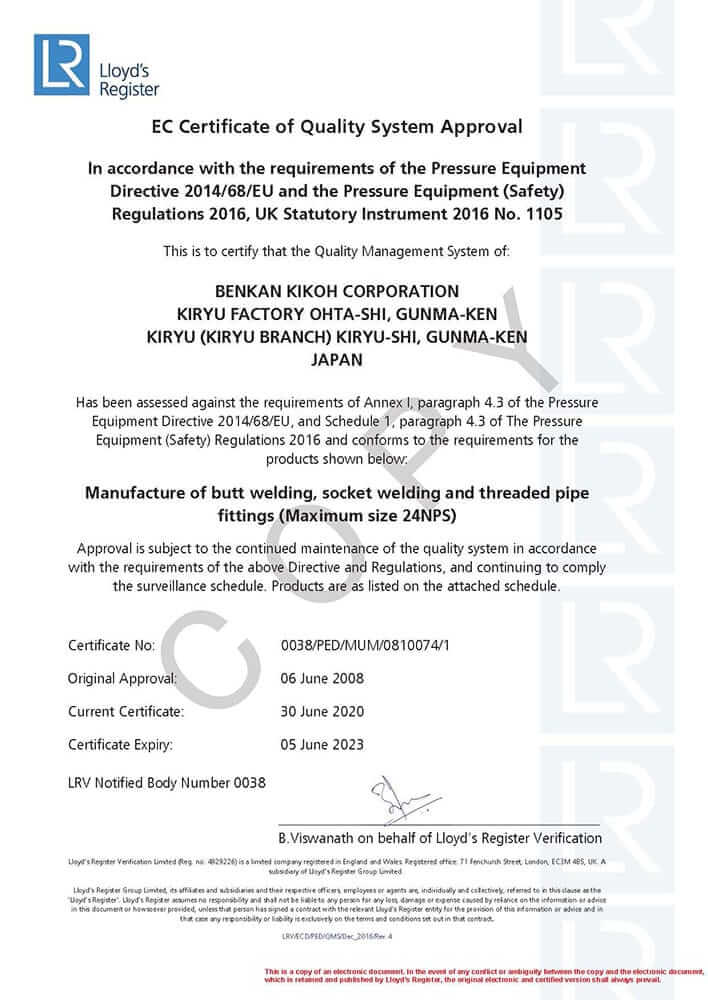

PED Approval Certificates

Pressure Equipment Directive 2014/68/EU

(Kiryu Factory)

Pressure Equipment Directive 2014/68/EU

(Osaka Factory)