High integration, High performance, rapid paced manufacturing processes for semiconductors depend mostly on gas-based systems.

The clean efficiency of these gas-based systems is said to be one of the factors for a major impact on the semiconductor industries future development.

The gas cylinders are the backbone of these systems, which are not able to achieve clean efficiency unless the gas cylinders are able to supply clean gas.

The SUMI-FINE series is a clean gas cylinder taking advantage of unique technology for a polished inner surface, therefore dealing with moisture, particles and other issues in response to a wide range of customer needs.

SUMI-FINE

Internally polished container types

| Material (Symbol) |

Internal Volume(L) |

Max Capacity Pressure (MPa) |

Outer Diameter (mm) |

Thickness (mm) |

Length (mm) |

Weight (kg) |

|---|---|---|---|---|---|---|

| Manganese Steel (M) |

40.0 | 14.7 | 232.0 | 6.1 | 1,190 | 46.5 |

| 46.7 | 14.7 | 232.0 | 6.1 | 1,370 | 53.5 | |

| Chromium-Molybdenum Steel (C) |

40.0 | 19.6 | 232.0 | 6.3 | 1,190 | 46.5 |

| 40.0 | 14.7 | 232.0 | 5.5 | 1,175 | 41.0 | |

| 50.0 | 19.6 | 232.0 | 6.3 | 1,460 | 56.5 | |

| 46.7 | 14.7 | 232.0 | 5.5 | 1,350 | 47.0 | |

| Stainless Steel (S) SUS304、316 |

46.7 | 5.88 | 232.0 | 6.3 | 1,370 | 53.5 |

| Stainless Steel 40L |

40.0 | 5.88 | 232.0 | 6.3 | 1,190 | 46.5 |

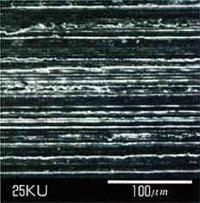

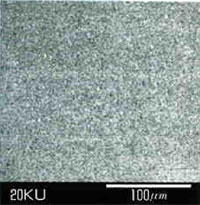

SUMI-FINE container polishing roughness

The roughness of the polishing is expressed as Rmax, which we make available for our customer’s requests at 25μm, 12μm, 6μm and 1μm.

Samples of the container polishing taken from SEM Factory

12μm (SUMI-FINE M12)

1μm (SUMI-FINE M1)